Kyocera AVX _Korat_SLR9_SLR16

Kyocera AVX _Korat_SLR9_SLR16

1595 Views

Project : AVX Korat

Location: Korat, Nakronrachasrima Province

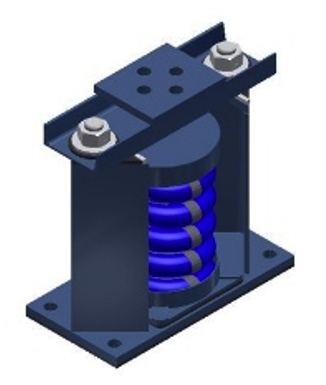

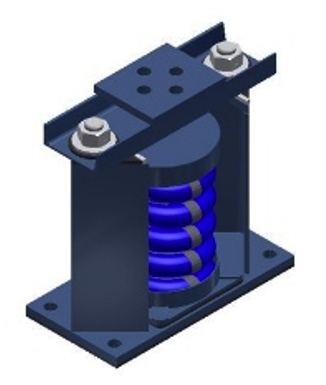

Specified Isolation Method : Restrained mount Springs

Model : SLR-6, SLR-9,SLR-12

Mechanical and electrical equipment can generate significant vibration that can travel through walls, floors and ceilings, flanking into adjoining rooms and buildings. If not treated effectively, this can cause noise and vibration to disturb staff, residents and also effect sensitive equipment. Mechanical vibration can even cause damage to the structure if significant vibration is generated.

This can lead to problems when this noise leaks into surrounding rooms. Not only will it affect the acoustic comfort of staff working in those rooms (reducing efficiency and causing stress) but it can even damage the building structure! It is for these reasons that it is crucial to install some form of vibration isolation in plant rooms.

The transmission of sound and vibration can be greatly reduced through the application of installation these springs Mason Industries has developed the very best equipment available for acoustically isolating plant room machinery. We can supply, and design vibration solutions for such equipment as AHU’s, A/C units, CHP units, pumps and more.

SLR

Restrained spring mountings shall have an SLF mounting as described in SLF Specification, within a rigid housing that includes vertical limit stops to prevent spring extension when weight is removed. The housing shall serve as blocking during erection. Installed and operating heights are equal. Restraining Bolts shall have a neoprene bushing between the bolt and the housing. A clearance of 1/4” (6mm) shall be maintained around restraining bolts and the bushing so as not to interfere with the spring action. Limit stops shall be out of contact during normal operation. Since housings will be bolted or welded in position there must be an internal isolation pad. Housing shall be designed to resist all seismic forces. Mountings shall have an OPA preapproval from OSHPD in the state of California certifying the maximum certified horizontal and vertical load ratings

MFTNC

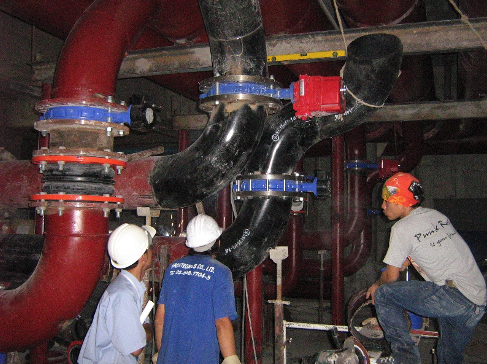

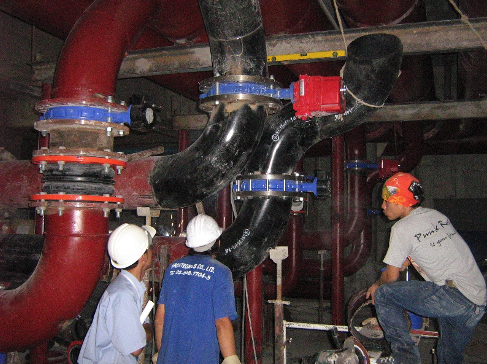

SUPER FLEX EXPANSION JOINTS

The SUPERFLEX elastomer was changed from Neoprene to EPDM as most applications are for water service. EPDM is superior to Neoprene in minimizing water swell and resistance to oxygen and ozone aging is outstanding. High temperature tolerance is much better as well.

All lengths were shortened to save space. The steel ring between the twin spheres prevented bulging, allowed for higher pressure ratings, reduced elongation and a higher range of pressures could be accommodated without the use of control rods.

Location: Korat, Nakronrachasrima Province

Specified Isolation Method : Restrained mount Springs

Model : SLR-6, SLR-9,SLR-12

Mechanical and electrical equipment can generate significant vibration that can travel through walls, floors and ceilings, flanking into adjoining rooms and buildings. If not treated effectively, this can cause noise and vibration to disturb staff, residents and also effect sensitive equipment. Mechanical vibration can even cause damage to the structure if significant vibration is generated.

This can lead to problems when this noise leaks into surrounding rooms. Not only will it affect the acoustic comfort of staff working in those rooms (reducing efficiency and causing stress) but it can even damage the building structure! It is for these reasons that it is crucial to install some form of vibration isolation in plant rooms.

The transmission of sound and vibration can be greatly reduced through the application of installation these springs Mason Industries has developed the very best equipment available for acoustically isolating plant room machinery. We can supply, and design vibration solutions for such equipment as AHU’s, A/C units, CHP units, pumps and more.

SLR

Restrained spring mountings shall have an SLF mounting as described in SLF Specification, within a rigid housing that includes vertical limit stops to prevent spring extension when weight is removed. The housing shall serve as blocking during erection. Installed and operating heights are equal. Restraining Bolts shall have a neoprene bushing between the bolt and the housing. A clearance of 1/4” (6mm) shall be maintained around restraining bolts and the bushing so as not to interfere with the spring action. Limit stops shall be out of contact during normal operation. Since housings will be bolted or welded in position there must be an internal isolation pad. Housing shall be designed to resist all seismic forces. Mountings shall have an OPA preapproval from OSHPD in the state of California certifying the maximum certified horizontal and vertical load ratings

MFTNC

SUPER FLEX EXPANSION JOINTS

The SUPERFLEX elastomer was changed from Neoprene to EPDM as most applications are for water service. EPDM is superior to Neoprene in minimizing water swell and resistance to oxygen and ozone aging is outstanding. High temperature tolerance is much better as well.

All lengths were shortened to save space. The steel ring between the twin spheres prevented bulging, allowed for higher pressure ratings, reduced elongation and a higher range of pressures could be accommodated without the use of control rods.