Rama Bangplee Hospital

Rama Bangplee Hospital

1265 Views

Project : Rama Bangplee Hospital

Location : Bangplee, Samutprakarn province

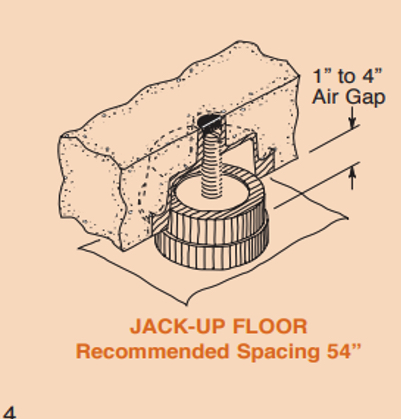

Specified Isolation Method: Jack up floating floor

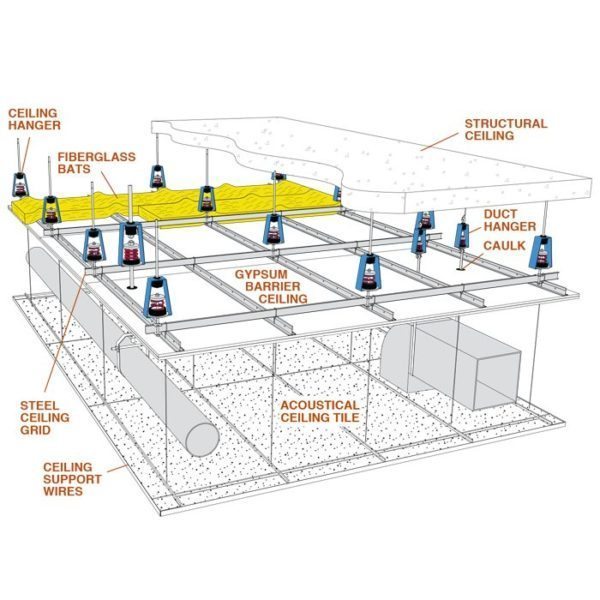

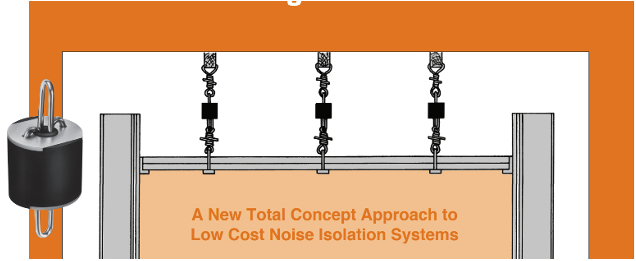

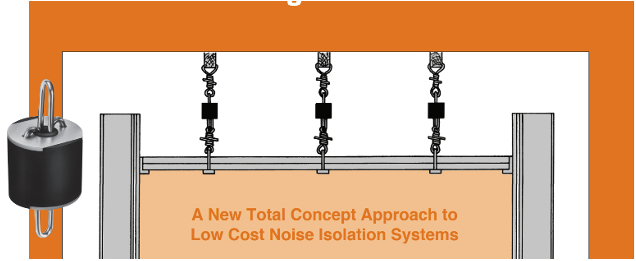

Floating Floors remain the most effective way of reducing sound transmission and vibration from the floor above. However, there are many situations where a floating floor is impractical or not economically feasible, so an isolated ceiling becomes the practical choice. Additionally, isolated walls are also an effective way to reduce sound transmission between rooms. The most effective system is a Box-in-box construction, where a floating floor, acoustic suspension ceiling and isolated walls are combined to create a room inside of a room

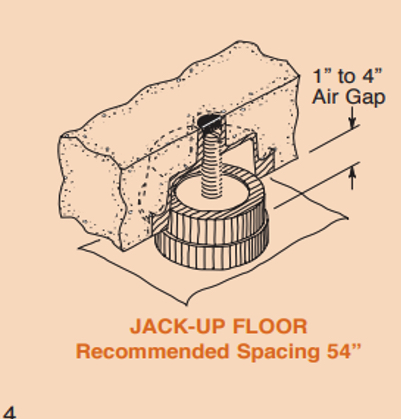

We believe that the most fool-proof and safest way to establish the air gap is the jack-up or lift-slab method. Plastic sheeting is placed on the sub-floor as a breaker layer, isolators are placed on the plastic sheeting, reinforcing steel or mesh rests on the isolator housings, and the concrete floor is poured. After the concrete has cured, the slab is lifted to elevation by turning adjustment bolts above each isolator to any specified air gap between 1” and 4”.

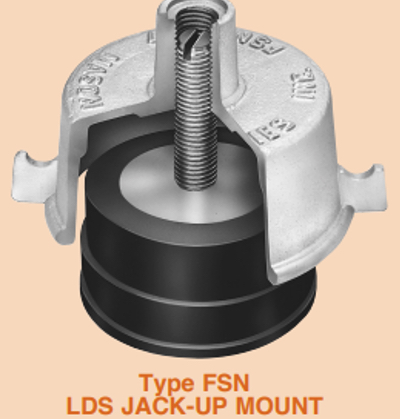

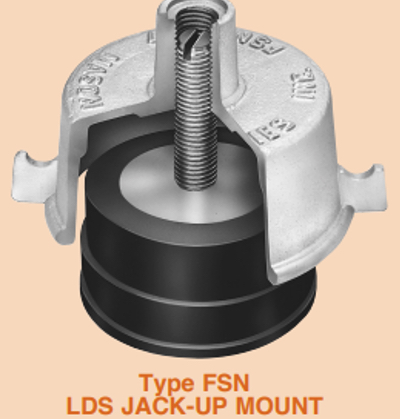

FSN

Bell shaped castings with integral lugs to locate reinforcing, shrouding 2”(50mm) thick LDS isolators molded to the following AASHTO bridge bearing specifications. All housings shall have 3/4”(20mm) minimum diameter jackscrews. Deflections shall not exceed 0.3”(7.5mm) nor the frequency 10Hz. Isolator shall be Mason Industries type FSN.

The Mason FSN Jack-Up acoustic floor system can be used as the crucial part of achieving box in box construction for rooms requiring a high level of acoustic separation or simply providing acoustic or impact isolation from one area to another.

WHR

Ceiling Hangers shall be fail safe and consist of opposed washers sandwiching an AASHTO Bridge Bearing Quality LDS Rubber Element 11/8” thick. Dynamic Stiffness shall not exceed 1.4” nor the corrected frequency 12 Hz. Connections shall be made with 12 gauge wire top and bottom passing through hairpin loops attached to the opposing washers. Ceiling Hangers shall be Mason Industries type WHR. Submittals shall confirm AASHTO Quality and Dynamic Stiffness in addition to frequency.

WIC

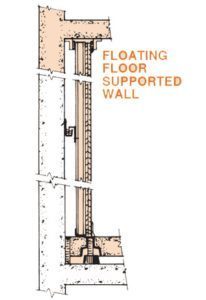

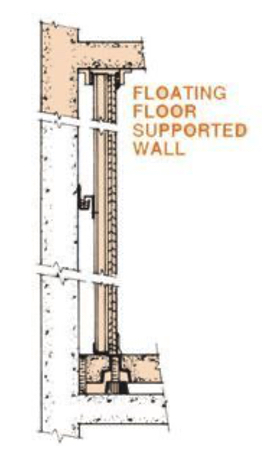

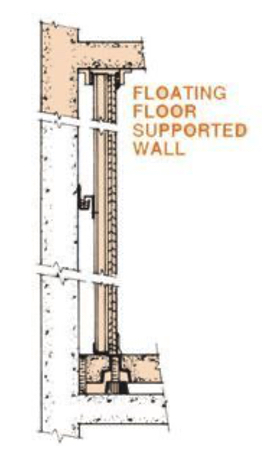

Floating walls and suspended ceilings complete the isolation. Walls should be resting on a continuous SWW pad, if not on the floating floor and sealed at the top with AB-716 angle brackets. Buckling is prevented by means of DNSB sway braces or the simpler WIC or WCL commonly used with fabricated walls. All of these devices use neoprene as the isolation media or natural rubber if specifically called for by an acoustical consultant.

It is often necessary to create a ‘Box in a box’ design. A ‘Box in a box’ design is where an internal room is built within the existing structure. This internal box is totally isolated acoustically from the surrounding building. This is achieved via a combination of air-gaps, LDS rubber (previously neoprene) and springs, depending upon loads and natural frequencies. These are built into the floors, walls and ceilings.

Location : Bangplee, Samutprakarn province

Specified Isolation Method: Jack up floating floor

Floating Floors remain the most effective way of reducing sound transmission and vibration from the floor above. However, there are many situations where a floating floor is impractical or not economically feasible, so an isolated ceiling becomes the practical choice. Additionally, isolated walls are also an effective way to reduce sound transmission between rooms. The most effective system is a Box-in-box construction, where a floating floor, acoustic suspension ceiling and isolated walls are combined to create a room inside of a room

We believe that the most fool-proof and safest way to establish the air gap is the jack-up or lift-slab method. Plastic sheeting is placed on the sub-floor as a breaker layer, isolators are placed on the plastic sheeting, reinforcing steel or mesh rests on the isolator housings, and the concrete floor is poured. After the concrete has cured, the slab is lifted to elevation by turning adjustment bolts above each isolator to any specified air gap between 1” and 4”.

FSN

Bell shaped castings with integral lugs to locate reinforcing, shrouding 2”(50mm) thick LDS isolators molded to the following AASHTO bridge bearing specifications. All housings shall have 3/4”(20mm) minimum diameter jackscrews. Deflections shall not exceed 0.3”(7.5mm) nor the frequency 10Hz. Isolator shall be Mason Industries type FSN.

The Mason FSN Jack-Up acoustic floor system can be used as the crucial part of achieving box in box construction for rooms requiring a high level of acoustic separation or simply providing acoustic or impact isolation from one area to another.

WHR

Ceiling Hangers shall be fail safe and consist of opposed washers sandwiching an AASHTO Bridge Bearing Quality LDS Rubber Element 11/8” thick. Dynamic Stiffness shall not exceed 1.4” nor the corrected frequency 12 Hz. Connections shall be made with 12 gauge wire top and bottom passing through hairpin loops attached to the opposing washers. Ceiling Hangers shall be Mason Industries type WHR. Submittals shall confirm AASHTO Quality and Dynamic Stiffness in addition to frequency.

WIC

Floating walls and suspended ceilings complete the isolation. Walls should be resting on a continuous SWW pad, if not on the floating floor and sealed at the top with AB-716 angle brackets. Buckling is prevented by means of DNSB sway braces or the simpler WIC or WCL commonly used with fabricated walls. All of these devices use neoprene as the isolation media or natural rubber if specifically called for by an acoustical consultant.

It is often necessary to create a ‘Box in a box’ design. A ‘Box in a box’ design is where an internal room is built within the existing structure. This internal box is totally isolated acoustically from the surrounding building. This is achieved via a combination of air-gaps, LDS rubber (previously neoprene) and springs, depending upon loads and natural frequencies. These are built into the floors, walls and ceilings.