Life One & Wireless

Life One & Wireless

1380 Views

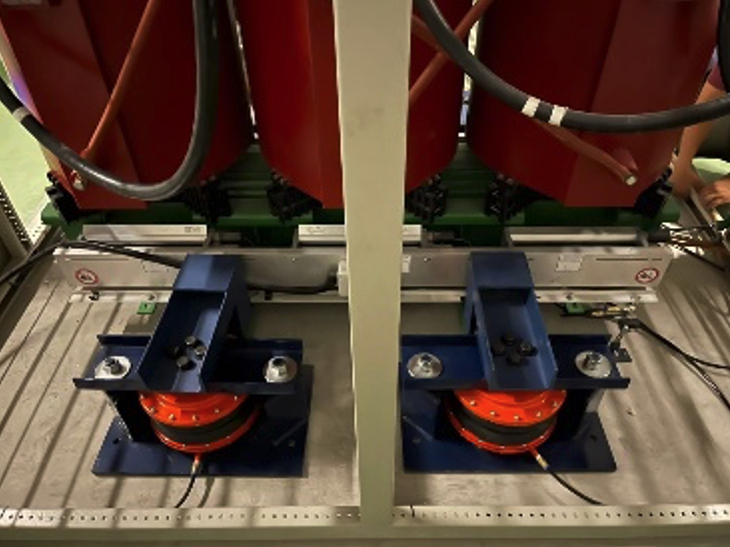

Project Name : Life One & Wireless

Location : Wireless road, Bangkok

Specified Isolation Method: Air spring

Problem: Low frequency noise from transformer room transfer to living room

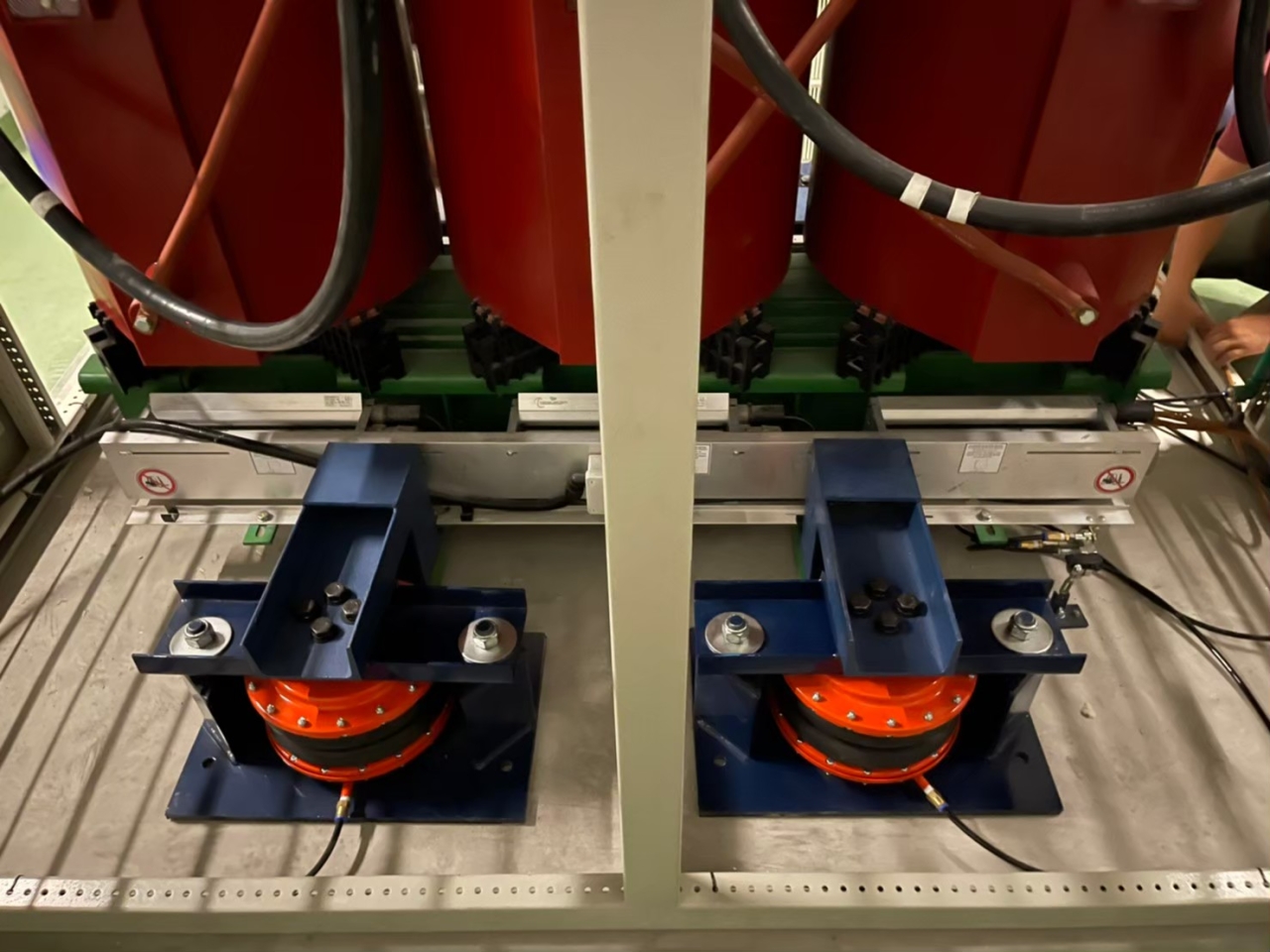

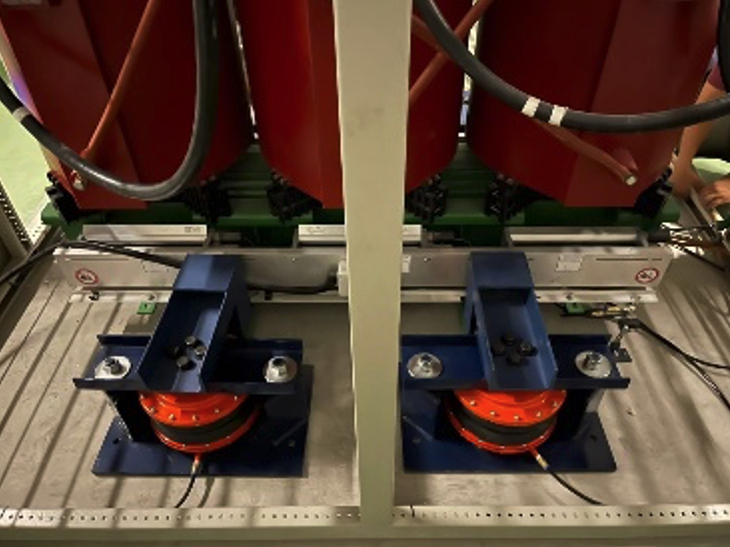

Solution: Support Air spring model SLRMT under transformer

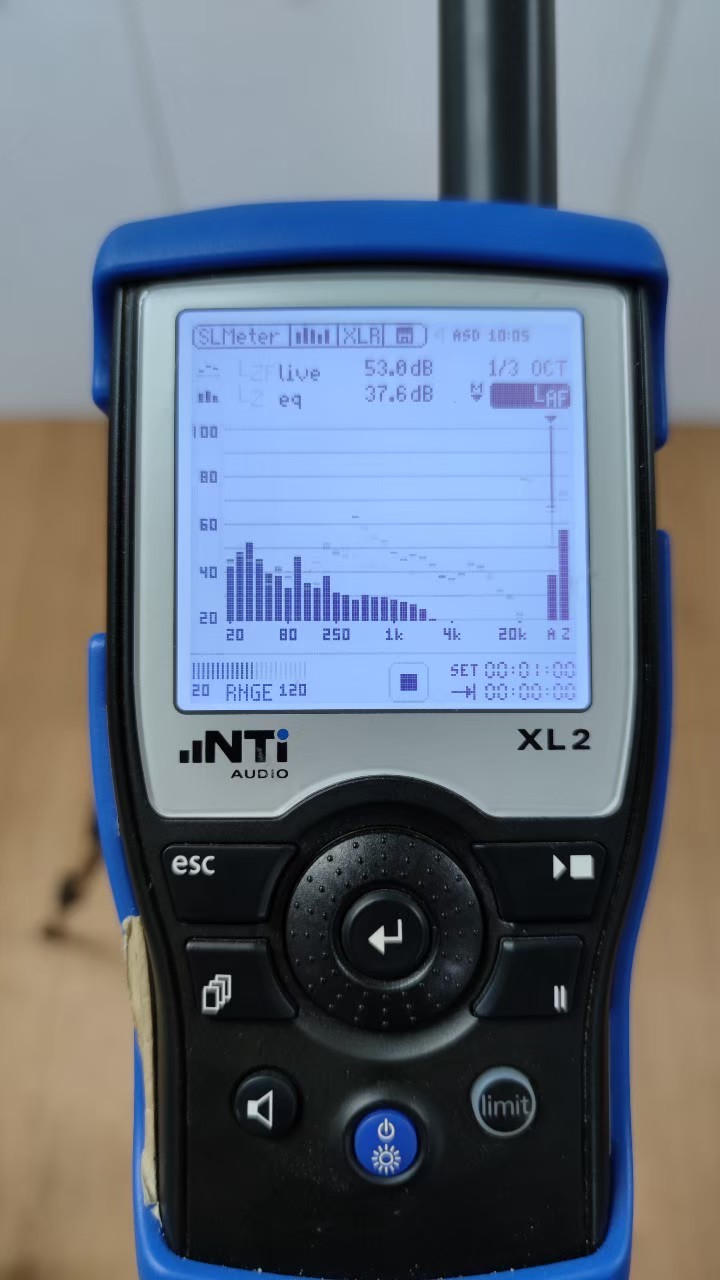

Result: Noise Measurement is NC standard for living room

While a rubber pad will reduce this noise, it has been our experience on many occasions that no matter how many layers of rubber pads were used (we have built up to 6”[150mm]), the noise will still find its way through. We never use pads harder than 60 durometers, but harder pads (65 duro and higher) are even more sound transparent. Air springs completely eliminate this problem.

Support is provided by pressurized air within a thin-walled rubber container similar to but lighter than the side walls of an automobile tire. We have never experienced high frequency noise transmission when using air springs, as the sound is not transmitted by the air or the tire cord reinforced neoprene body. There is always some air leakage no matter how slow.

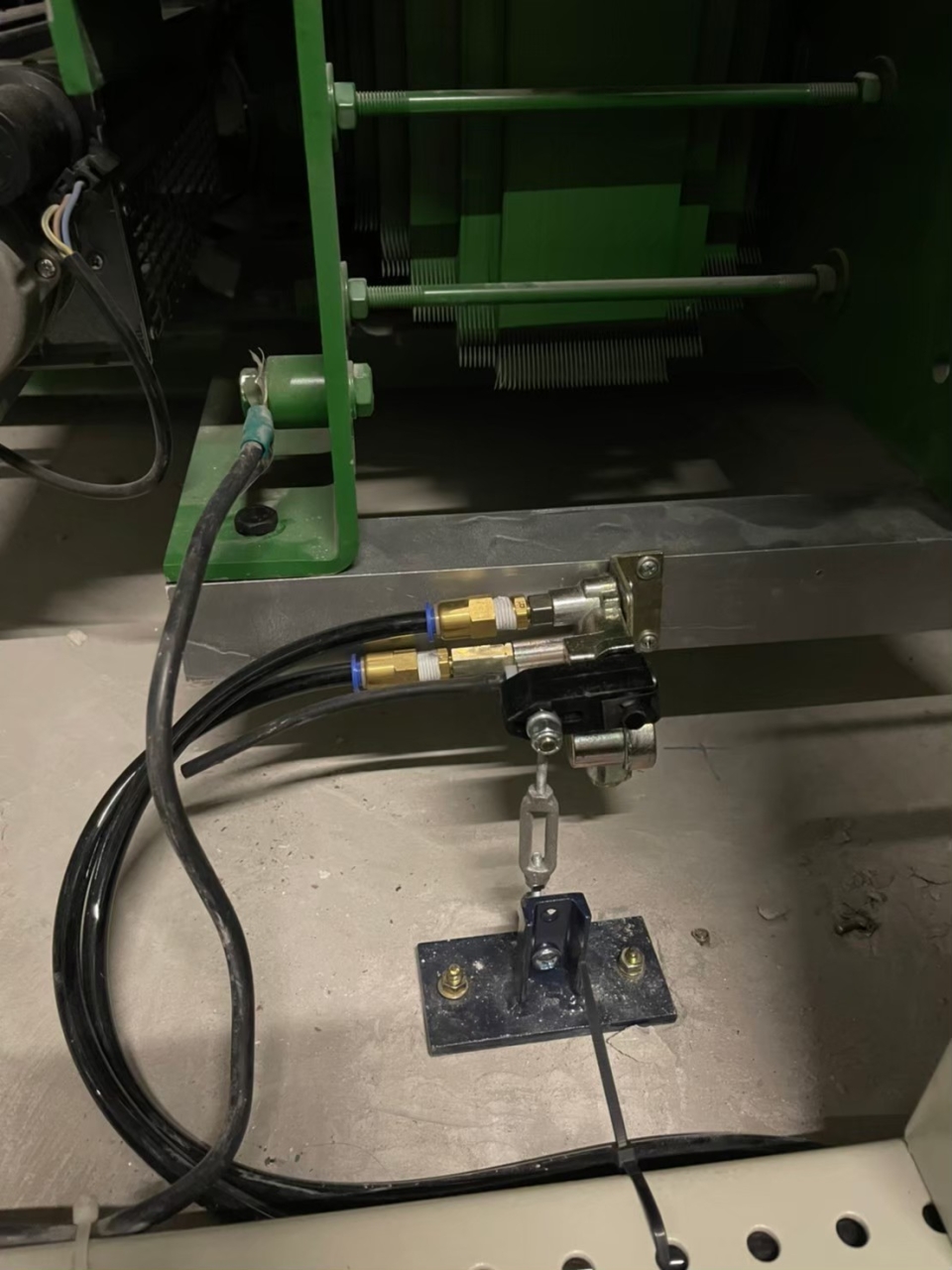

After systems are installed, they are seldom inspected and maintained. Our experience has proven it is mandatory that the air springs are installed with an air supply and height sensitive (not pressure sensitive) control valves. The valves provide additional air if elevation is lost or vent if the elevation increases due to rotational forces or temperature increase. Temperature increases occur on hot roofs or within transformer vaults. Air usage is minimal. Most of the time the system is supplied by control air. If not available, the smallest available tank type compressor is more than adequate if it will operate at the air spring rated pressure. This compressor is often mounted on the primary equipment so it is self-isolated. We strongly recommend air springs in critical areas where noise transmission is a major worry.

Air Springs are typically used to isolate equipment that is very sensitive to vibration. They provide very high levels of isolation, can reach very low natural frequencies and are essentially resonance free.

Typical applications include medical scanners or high precision imaging equipment such as electron microscopes. Some types of electrical transformers require isolation via air springs due to their inherently complex vibration modes.

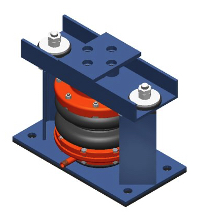

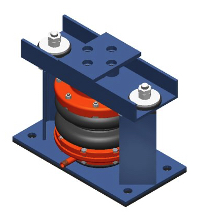

SLR-MT – Welded Restrained Twin Sphere Air Spring Mounts

Multiple bellow air springs shall be manufactured with powder coated upper and lower steel sections connected by a replaceable, flexible Nylon reinforced Neoprene element to achieve a maximum natural frequency of 3 Hz. (We have found 3 Hz adequate when using air springs. Should the specifying engineer require a lower frequency, change the 3 Hz to the lower number). Burst pressure must be a minimum of 3 times the published maximum operating pressure. All air spring systems shall be equipped with 3 leveling valves connected to the building control air or a supplementary air supply to maintain elevation plus or minus 1/8” (3mm). An air filter and water separator shall be installed before the air distribution system to the leveling valves

Submittals shall include natural frequency, as well as load and damping tests, all as performed by an independent lab or acoustician. Air springs shall be type MT and leveling valves type LV as manufactured by Mason Industries, Inc.

Restrained air spring mountings shall have an MT air spring as described in MT Specification, within a rigid housing that includes vertical limit stops to prevent air spring extension when weight is removed. The housing shall serve as blocking during erection. A steel spacer shall be removed after adjustment. Installed and operating heights are equal. A clearance of 1/4” (6mm) shall be maintained around restraining bolts and between the housing and the air spring so as not to interfere with the air spring action. Limit stops shall be out of contact during normal operation. Housing shall be designed to resist all seismic forces. Mountings shall be type SLRMT as manufactured by Mason Industries, Inc.

Location : Wireless road, Bangkok

Specified Isolation Method: Air spring

Problem: Low frequency noise from transformer room transfer to living room

Solution: Support Air spring model SLRMT under transformer

Result: Noise Measurement is NC standard for living room

While a rubber pad will reduce this noise, it has been our experience on many occasions that no matter how many layers of rubber pads were used (we have built up to 6”[150mm]), the noise will still find its way through. We never use pads harder than 60 durometers, but harder pads (65 duro and higher) are even more sound transparent. Air springs completely eliminate this problem.

Support is provided by pressurized air within a thin-walled rubber container similar to but lighter than the side walls of an automobile tire. We have never experienced high frequency noise transmission when using air springs, as the sound is not transmitted by the air or the tire cord reinforced neoprene body. There is always some air leakage no matter how slow.

After systems are installed, they are seldom inspected and maintained. Our experience has proven it is mandatory that the air springs are installed with an air supply and height sensitive (not pressure sensitive) control valves. The valves provide additional air if elevation is lost or vent if the elevation increases due to rotational forces or temperature increase. Temperature increases occur on hot roofs or within transformer vaults. Air usage is minimal. Most of the time the system is supplied by control air. If not available, the smallest available tank type compressor is more than adequate if it will operate at the air spring rated pressure. This compressor is often mounted on the primary equipment so it is self-isolated. We strongly recommend air springs in critical areas where noise transmission is a major worry.

Air Springs are typically used to isolate equipment that is very sensitive to vibration. They provide very high levels of isolation, can reach very low natural frequencies and are essentially resonance free.

Typical applications include medical scanners or high precision imaging equipment such as electron microscopes. Some types of electrical transformers require isolation via air springs due to their inherently complex vibration modes.

SLR-MT – Welded Restrained Twin Sphere Air Spring Mounts

Multiple bellow air springs shall be manufactured with powder coated upper and lower steel sections connected by a replaceable, flexible Nylon reinforced Neoprene element to achieve a maximum natural frequency of 3 Hz. (We have found 3 Hz adequate when using air springs. Should the specifying engineer require a lower frequency, change the 3 Hz to the lower number). Burst pressure must be a minimum of 3 times the published maximum operating pressure. All air spring systems shall be equipped with 3 leveling valves connected to the building control air or a supplementary air supply to maintain elevation plus or minus 1/8” (3mm). An air filter and water separator shall be installed before the air distribution system to the leveling valves

Submittals shall include natural frequency, as well as load and damping tests, all as performed by an independent lab or acoustician. Air springs shall be type MT and leveling valves type LV as manufactured by Mason Industries, Inc.

Restrained air spring mountings shall have an MT air spring as described in MT Specification, within a rigid housing that includes vertical limit stops to prevent air spring extension when weight is removed. The housing shall serve as blocking during erection. A steel spacer shall be removed after adjustment. Installed and operating heights are equal. A clearance of 1/4” (6mm) shall be maintained around restraining bolts and between the housing and the air spring so as not to interfere with the air spring action. Limit stops shall be out of contact during normal operation. Housing shall be designed to resist all seismic forces. Mountings shall be type SLRMT as manufactured by Mason Industries, Inc.